This article was co-written by Will Patterson and Sandhya Mahadevan

This is an excerpt from the March 2018 edition of The SOL SOURCE, a monthly electronic newsletter analyzing the latest trends in renewable energy based on our unique position in the solar industry. To receive future editions of the journal, please subscribe.

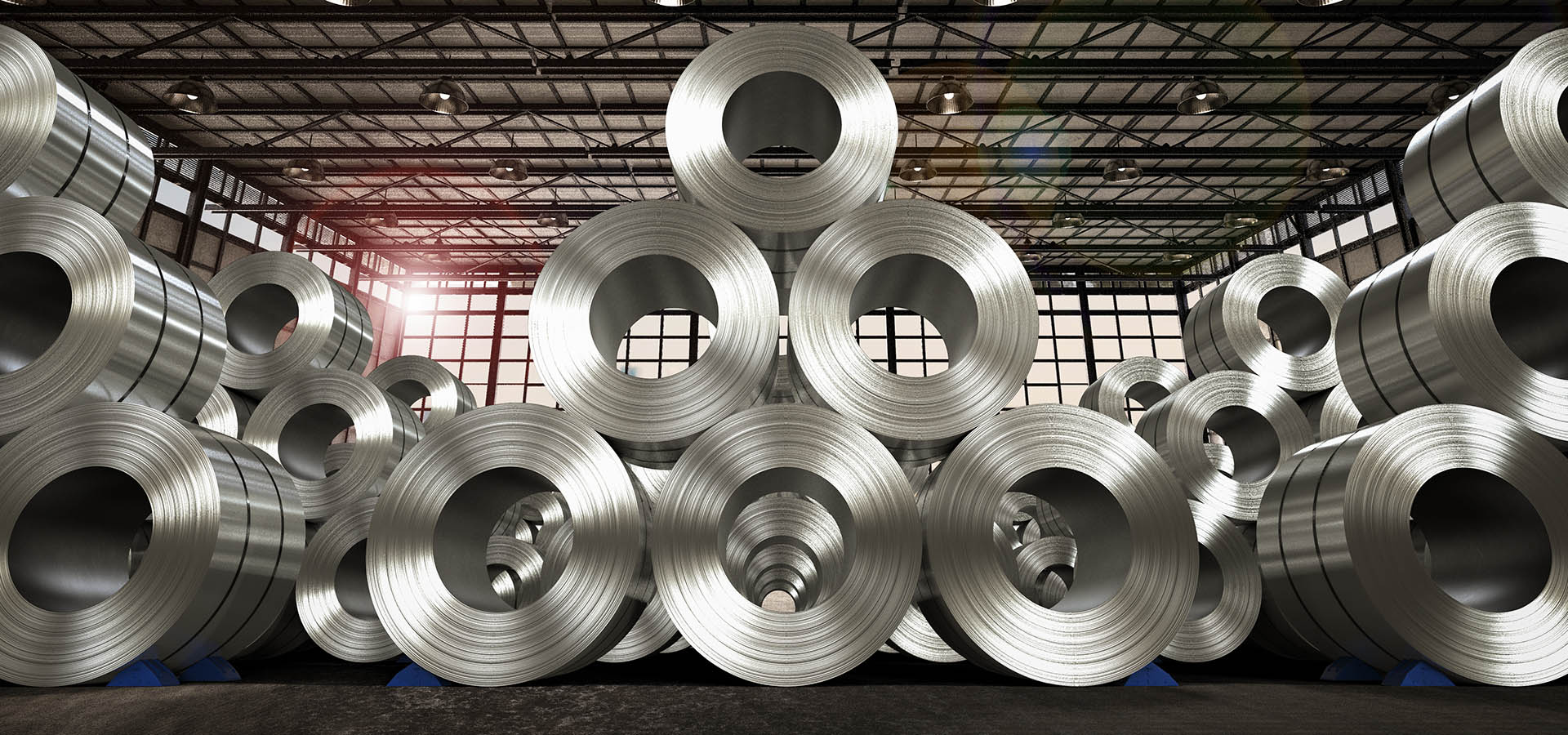

On Friday, March 23, two months after the White House enacted sweeping tariffs on imported solar panels and cells, new tariffs on imported steel and aluminum, materials also used in solar installations, will be put into effect by the Trump administration. The tariffs will hurt many industries across the country, the solar industry included. We’ve seen calculations from SEIA and GTM on the price increases tariffs will cause on a national scale for solar project development. However, on the micro level, the tariffs will make certain state markets tougher and push against current trends.

Another Tariff on Solar

Solar is still recovering, both financially and emotionally, from the 30 percent tariffs on imported solar cells and panels. The solar tariffs that loomed for most of last year partly contributed to the 30 percent year-over-year decline in installations in 2017 and are estimated to reduce industry growth by 10 to 15 percent. Although solar still maintains a good foothold on its future – and we firmly believe still that solar is on a path to dominance - steel tariffs further threaten its potential.

The tariffs, which amount to 25 percent on imported steel and 10 percent on imported aluminum, cover materials essential to solar installations. Steel is used in most ground-mount trackers, racks, and carports structures, while aluminum is commonly used in commercial and residential racking structures. Although these materials are often sourced in America, imports of these material comprise enough of these installations to make an impact.

Where Steel Counts Most: Carports

While the majority of buzz about the steel tariff has been about its impacts on solar at a national level, the prominence of specific types of solar deployment in certain states may cause the tariff to impact different market sectors and geographies in varying degrees. Some project types, like carports and trackers, require more steel than others. Carports, for instance, require steel columns to hold the canopies, and trackers require steel columns to support the panels as well.

As we've discussed previously, some state incentive programs, like the Solar Massachusetts Renewable Tariff (SMART) program, provide incentives for specific technologies like carports and dual-axis trackers. Coupled with the recent buzz of an additional carport incentive in NY’s revamped Megawatt Block program, carports have become a much more popular option for solar in the dense Northeast. However, according to analysis from the Sol Systems engineering team, carports are likely to experience cost increases between $0.08-$0.12/W, which represent the largest cost increases of any specific deployment of solar.

The carport adder under the SMART program is $0.06/kWh, which is meant to offset the existing price premiums for the technology, which is it currently able to do. While the tariff has increased the cost of building carports, the prices are not so insurmountable to preclude building them. Additionally, kWh incentives for carports allow developers to offset the cost premium on steel by using higher yield panels, as the project receives incentives for the energy it produces, rather than its size alone. However, pair together steel tariffs, Section 201 tariffs increasing the price of solar cells and modules, and then very high interconnection costs, and this trifecta is certainty not helpful for carport development.

Steel & Trackers

While single axis trackers are less popular in the Northeast due to the heavy snow loads they would need to endure, they are much more common for projects in the Midwest. For example, in Illinois, trackers are preferred because they allow the project to maximize its yield while staying within the 2 MWac size limit of the Adjustable Block Program. However, in contrast to carports, our analysis indicates trackers and rooftop projects will only increase by $0.03-$0.05/W and $0.015-$0.03/W, respectively.

Steel Your Heart, Solar

Tariffs on steel hurt the large majority of energy sources, and price hikes in solar projects will be equaled in competing sources as well. We also can’t be sure how long these tariffs will last, as previous tariffs on steel have succumbed to the threats of a trade war, a very real possibility today. It is also possible that more countries will be given exemptions, as Canada and Mexico have, that could lessen the impact.

Although these tariffs are both ill-timed and costly, the solar industry continues to be in great position to succeed now and in the future. Solar will take a hit from the steel tariffs, but like with all its speedbumps in the past, it will take it in stride. For customers curious about the effect of tariffs on their plans to go solar, please reach out to the Sol Systems team at energyservices@solsytems.com. We’d be happy to assist.

ABOUT SOL SYSTEMS

Sol Systems, a national solar finance and development firm, delivers sophisticated, customized services for institutional, corporate, and municipal customers. Sol is employee-owned, and has been profitable since inception in 2008. Sol is backed by Sempra Energy, a $25+ billion energy company.

Over the last nine years, Sol Systems has delivered 650MW of solar projects for Fortune 100 companies, municipalities, universities, churches, and small businesses. Sol now manages over $650 million in solar energy assets for utilities, banks, and Fortune 500 companies.

Inc. 5000 recognized Sol Systems in its annual list of the nation’s fastest-growing private companies for four consecutive years. For more information, please visit www.solsystems.com.