This article is part of the March 2023 edition of our publication The Sol SOURCE. Click here to read the full publication.

The agricultural and solar industries sometimes compete for land use, but they have recently found ways to work together. Agrivoltaics is the use of land below solar panels for crop fields, allowing a site to produce both food and energy. To better understand how these dual uses interact, we researched how yields for lettuce, a cash crop that can produce in shaded conditions, might benefit from changes to solar panel configuration at a projected growing site near Fresno, California. We found that some configurations are well suited to both agricultural productivity and project returns.

Research Methods

Our team evaluated four system configurations:

- a fixed ground-mounted system with one-meter ground clearance;

- a fixed elevated system with 3.75-meter ground clearance;

- a single-axis tracking ground-mounted system with one-meter ground clearance; and

- a single-axis tracking elevated system with 3.75-meter ground clearance.

We measured the effect on lettuce yield of adjustments to ground-clearance height, array height, axis selection, tilt, tracking rotation limit, and backtracking.

Row spacing was set to approximately four meters between panels, allowing lettuce positioning between rows to conform to standard 14-inch spacing, including 14 inches from the system’s standard 20-inch-diameter support piling. The yield was measured under normal and drought conditions to monitor crop response to variable moisture retention. Reduced moisture retention in drought conditions results in greater production when panels are positioned over the lettuce, enhancing yield for ground-mounted panels and elevated arrays.

Using all input parameters, we created 25 plots of subarrays containing 20 rows per subarray and 16 modules per row, occupying a total of seven acres of land. Differences in assumed yield were calculated based on average photosynthesis. System costs were adjusted to reflect increased labor and materials costs of elevating panels on stilts and installing trackers.

Results and Conclusion

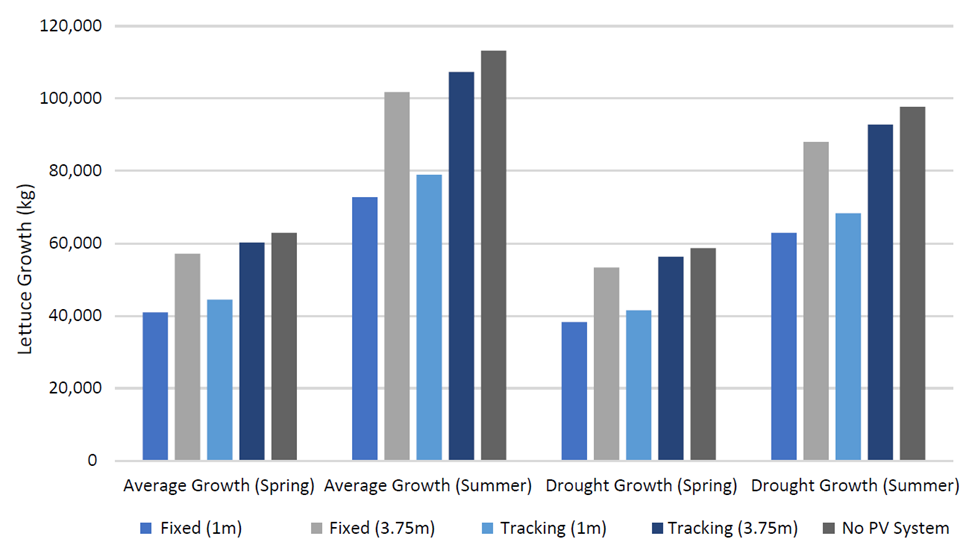

Total lettuce output for each system parameter demonstrated that elevating panels is key to increasing lettuce yield. Tracking also increases yield, although to a lesser extent.

The cost-adjusted financial results for each array design showed that the fixed elevated system generated the highest net present value, while the ground-mounted tracking system generated the highest internal rate of return (IRR).The elevated tracking system maximized lettuce yield, generated the highest total income, and generated a greater IRR than both fixed systems. The single-axis tracking array with 3.75-meter ground clearance resulted in the smallest reduction in lettuce yield compared to full-irradiance growing conditions. Importantly, an elevated system design would allow tractors averaging three meters in height to pass under the array, allowing farmers to use typical harvesting techniques. Unelevated ground-mounted systems would require harvesting by hand, necessitating special protective equipment for workers operating near the panels.

Further research into the potential of agrivoltaics is essential to improving land use in the clean-energy economy. More detailed data and citation information are available upon request.

Endnotes

1. Barron-Gafford, Pavao-Zuckerman, Minor, Sutter, Barnett-Moreno, Blackett, Thompson, Dimond, Gerlak, Nabhan, and Macknick (2019), Agrivoltatics provide mutual benefits across the food-energy-water nexus in drylands, Nature Sustainability.

2. Tani, Suguru, Nakashima, and Hayashi (2014), Improvement in lettuce growth by light diffusion under solar panels, Journal of Agricultural Meteorology.